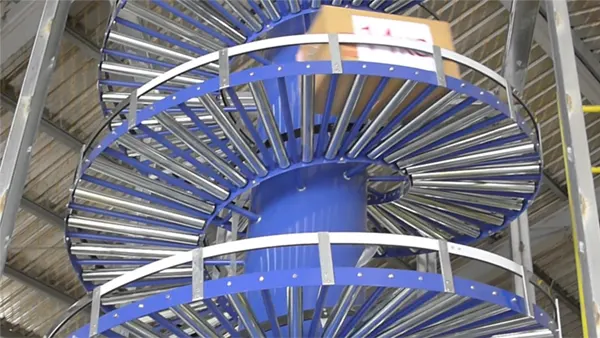

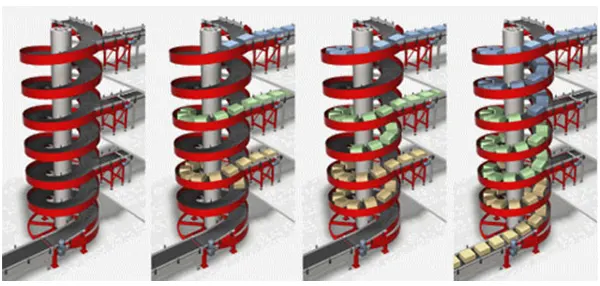

Spiral conveyors include a continuous process such as proofing, cooling, or freezing. In its simplest form, a tension spiral consists of an upright motor-driven drum or cage, and a side flex conveyor belt is wrapped around it.

The conveyor belt moves either up or down in a curled path and is supported by continuous belt support rails fixed to the other frame of the conveyor in a helical way.

Factors Need to Consider While Using Spiral Conveyors

When conveyor lines need to change elevations, they address many common factors and challenges when moving products from one level to another. Some of them are:

- The slope can’t be too steep, or a longer conveyor length will be required.

- You must consider the type of goods you are carrying.

- Taking the long stretch of a gradually sloped conveyor will help you.

Features & Benefits

- Easy to install.

- By conveying the product vertically, you can maximize the floor space.

- Effective and more efficient than elevators.

- allows you to customize the spirals to fit many applications.

Standard Spiral Conveyor Sizes

Special sizes can be manufactured to suit your applications. Standard sizes are:

| Belt Width | Effective Belt Width | Inside Belt Radius | Outside Frame Diameter |

| 254 mm | 234 mm | 381 mm | 1270 mm |

| 305 mm | 285 mm | 458 mm | 1526 mm |

| 406 mm | 386 mm | 609 mm | 2030 mm |

| 508 mm | 488 mm | 762 mm | 2540 mm |

| 610 mm | 590 mm | 915 mm | 3050 mm |

| 660 mm | 640 mm | 990 mm | 3300 mm |

| 762 mm | 742 mm | 1143 mm | 3810 mm |

| 813 mm | 793 mm | 1220 mm | 4066 mm |

| 1016 mm | 996 mm | 1524 mm | 5080 mm |

Pros of Spiral Conveyors

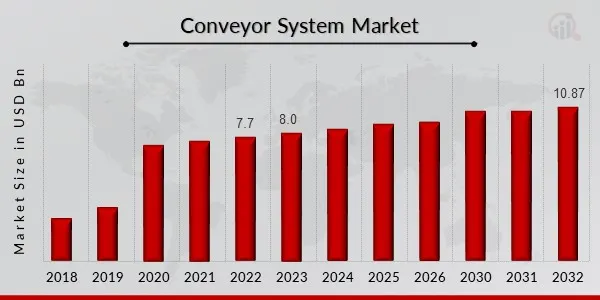

(This graph shows the conveyor system market size in US$ Billion).

Some attractive set of benefits a business can get while using them:

- Superior Product Handling

The all-plastic contact surface ensures an excellent product release of unpacked food products such as poultry, meat, and fish. In addition, the open spiral structure allows for an extensive open area.

- Optimize floor capacity

The Spiral conveyor systems have a compact and space-saving floor design. They optimize your floor capacity with their small footprint and a curve radius of 1.5 x width. The tight carrier fits into almost any plant structure.

- Long tracks and fewer transfers

Using bearings in the chain ensures a low friction coefficient and helps the curl be managed by just one motor for up to 50 meters in length. In addition, long spiral conveyor tracks mean fewer transfers and economical conveyance.

- Easy Access for Maintenance

The open design of the carrier system offers clear access for maintenance and wash-down and helps to reduce maintenance costs and better belt sanitation.

Cons of Spiral Conveyors

Some of the drawbacks of using Spiral Conveyors are:

- Provides limited conveying distance (30m per screw)

- Can degrade the particle and poor carrying of high friction

- Metal-on-metal contact can cause contamination

Spiral Conveyor— How does it work?

They are also known as vibratory bowl feeders, pot feeders, or vibratory bowl feeders. You can trace these names back to their specific design and their mode of operation: The sorting top of this transporter is like a pot, a tightly connected cylindrical coil known as a Helix.

Concerning the helical conveyor track or the carrier bowl, it also makes a distinction between cylindrical shape, step shape, and conical shape. The mode of operation is relatively simple: The conveyor tracks the bowl feeder’s vibration by an electromagnetic oscillating drive.

With this vibration, you can move the object in the desired direction and initiate a throwing motion called micro-throwing. You can also install the sorting element known as baffles manually. However, depending on the design of it, it is possible to make modifications that allow the baffles to change the transport items.

Changing the conveying speed by changing the vibration strength or vibration frequency is possible. Various additional elements can be connected, such as temperature regulation. Apart from curled coolers, there are also heating spiral conveyors, which ensure that the temperature of the items rises regularly.